- HOME

- Lab Equipment

- Air pollution control

- Wet Scrubber

Lab Equipment

High-Quality Taiwanese Manufacturing Local Suppliers

Air pollution control

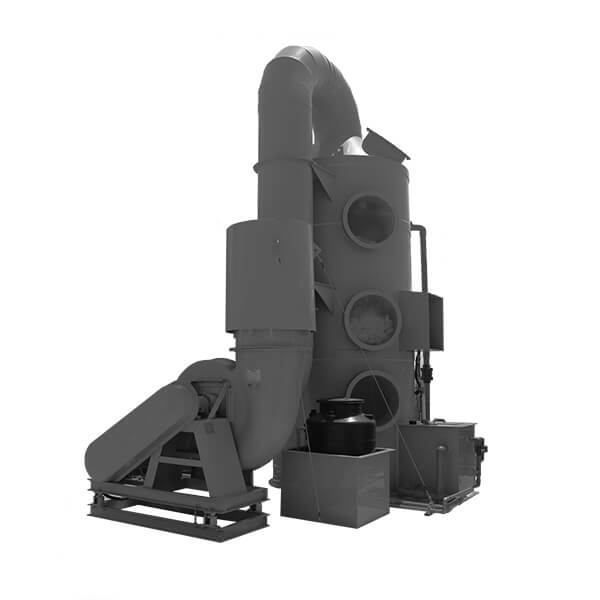

Wet Scrubber

Wet scrubbers are used to treat exhaust gases containing soluble pollutants. They utilize water or another liquid as a scrubbing agent, allowing the polluted air to pass through a water column or tower packing to absorb pollutants. They can also remove coarse dust particles from the exhaust gas.

Wet scrubbers can effectively control water-soluble pollutants such as sulfuric acid, hydrochloric acid, hydrofluoric acid, nitric acid, and ammonia in the waste exhaust./>

Scrubber classification

Scrubber classification

- Counterflow vertical design: In the vertical tower, the scrubbing absorbent is sprayed from top to bottom, while the gas flows upward from the bottom. This counterflow configuration is known for achieving higher treatment efficiency and is a prevalent design in the current market.

- Horizontal cross-flow design: The gas and scrubbing liquid flow directions are perpendicular to each other. This design is suitable for spaces with height limitations or complex exhaust systems requiring segmented treatment with multiple liquid additives.

- Indoor Scrubbing Tower: Operates in a countercurrent vertical manner, specifically designed for pre-treatment in highly polluting processes and laboratory fume hood applications.

.jpg)

| Material | Scrubbing Tower, Fan: PP | Ductwork: PP | Supply and Drainage Pipes: PVC |

| Color | Scrubbing Tower, Fan, Ductwork: Beige gray |

| Electricity usage | 3-phase 3-wire 220 volts 60 Hertz + G (ground)、3-phase 4-wire 380 volts 60 Hertz + G (ground) |

| Pressure drop | 40 mmAq |

| Packing | 3”tellerette |

| Ntake temperature | below 60 degrees Celsius |

| Pollutants | Formula | Efficiency% | Note |

| Hydrochloric acid | Hcl | 80% ~ 98% | NaOH add |

| Hydrogen fluoride | HF | 80% ~ 95% | NaOH add |

| Nitric acid | HNO3 | 70% ~ 90% | NaOH add |

| Sulphuric acid | H2SO4 | > 90% ~ 99% | NaOH add |

| Hydrogen sulphide | H2S | 80% ~ 95% | NaOH add/multi-channel |

| Ammonia | NH3 | 80% ~ 98% | H2SO4 add/multi-channel |

| Sodium hydroxide | NaOH | 80% ~ 98% | H2SO4 add |

| Material | Airflow CMM |

Water flow L/min |

Horsepower* Quantity |

Size | OIperating weight Kg |

Air velocity m/sec |

||

| Diameter Ømm |

High mm |

Inlet/Outlet diameter Ømm |

||||||

| RS030 | 30 | 65 | 1/2HP*1 | 600 | 3300 | 250 | 554 | 1.9 |

| RS050 | 50 | 150 | 1HP*1 | 760 | 3550 | 300 | 758 | 2.0 |

| RS080 | 80 | 250 | 2HP*1 | 960 | 3700 | 400 | 1078 | 2.0 |

| RS150 | 130 | 320 | 3HP*1 | 1300 | 4100 | 500 | 1825 | 2.0 |

| RS210 | 210 | 600 | 5HP*1 | 1530 | 4150 | 600 | 2634 | 2.0 |

| RS250 | 250 | 750 | 7.5HP*1 | 1700 | 4300 | 700 | 3223 | 2.0 |

| RS350 | 350 | 750 | 7.5HP*1 | 2000 | 4500 | 800 | 3978 | 2.0 |

| RS450 | 450 | 900 | 10HP*1 | 2290 | 4700 | 900 | 4846 | 2.0 |

| RS550 | 550 | 1200 | 5HP*2 | 2500 | 4900 | 1000 | 5827 | 2.0 |

| RS700 | 700 | 1500 | 7.5HP*2 | 2900 | 5100 | 1100 | 7622 | 1.9 |

| RS800 | 800 | 1800 | 10HP*2 | 3060 | 5200 | 1200 | 8578 | 1.9 |

Note:Specifications are for reference only

- ReferenceClick to enlarge image

- More

Related products

Facebook

Facebook LINE

LINE Shopee

Shopee